Earthen walls (tsuchi kabe) are a cornerstone of traditional Japanese architecture, embodying both durability and sustainability. Their ability to be reused positions them as a critical component in envisioning a future where construction aligns with environmental consciousness. This article delves into the layered structure of earthen walls, the challenges of reusing them, and their potential role in sustainable architecture.

The Three Layers of Earthen Walls

Traditional earthen walls are composed of three distinct layers:

- Base Layer (shitanuri): High clay content ensures structural integrity.

- Middle Layer (nakanuri): Balances clay and sand for improved strength.

- Top Layer (uwanuri): Higher sand content provides a smooth finish and aesthetic appeal.

This multi-layered approach enhances the wall’s durability, insulation properties, and adaptability to seasonal changes.

The Reusability of Earthen Walls

The Process and Its Benefits

One of the most remarkable features of traditional earthen walls is their reusability. While the base layer is often reusable even when mixed with middle-layer soil, the top layer and plaster (shikkui) typically require fresh materials to maintain quality. Reuse usually involves mixing 50% new base-layer soil to maintain stability.

The benefits of reusing earthen wall materials include:

- Shortened Fermentation Period: Recycled materials reduce the fermentation time from several months to just 1–2 months, saving time in preparation.

- Cost Efficiency: Reusing materials reduces the need to purchase new soil, lowering overall costs.

- Waste Reduction: By repurposing existing materials, the volume of industrial waste is significantly decreased, contributing to environmental sustainability.

Challenges in Reusing Earthen Walls

Despite its advantages, the reuse of earthen walls presents several obstacles:

Storage Issues

Preserving earthen materials requires protection from rain and ultraviolet rays, which necessitates careful storage and management. Past attempts to lease land for storage have failed due to logistical difficulties, highlighting the need for innovative solutions.

Loan Restrictions

Most housing loans require construction to be completed within one year, making it challenging to integrate the extended fermentation and drying periods necessary for earthen wall reuse. This limitation restricts widespread adoption.

Extended Drying Time

Each layer of an earthen wall requires approximately one month to dry. For walls with three layers on each side, the total drying time exceeds six months, often extending project timelines and increasing costs.

Reusing Materials and Addressing Industrial Waste

Construction generates vast amounts of industrial waste, such as tiles, wood scraps, and debris. The disposal of these materials is not only expensive but also environmentally damaging.

Innovative Reuse Practices

Efforts are being made to repurpose construction waste creatively:

- Roof Tiles: Repurposed as low fences or garden edging.

- Wood Scraps: Used as fuel for wood stoves or incorporated into furniture projects.

These practices not only reduce waste but also add value to renovations, particularly in preserving and repurposing elements of traditional homes.

Earthen Walls and the Future of Architecture

Minimizing Waste with Traditional Methods

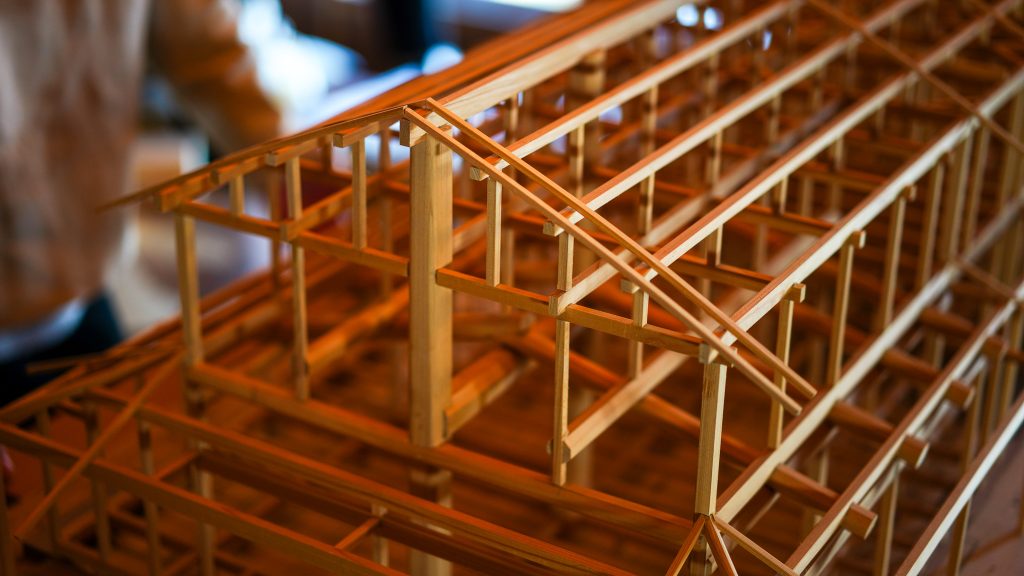

Construction techniques like the ishibadate stone-foundation method inherently produce less waste. Utilizing natural materials such as wood, bamboo, and straw, these methods align with eco-friendly principles. However, high costs limit their adoption.

Leveraging Technology to Revive Tradition

Advances in AI and automated processing technologies may lower the cost of traditional construction methods, making them more accessible. However, the most critical shift involves focusing on how existing buildings can be repurposed, rather than constructing new ones.

Addressing Japan’s Vacant Home Problem

Japan faces a growing problem of vacant homes (akiya). Renovating these structures offers an opportunity to integrate sustainable practices, including the reuse of earthen walls and other traditional elements. Renovations also reduce the demand for new construction, conserving resources and reducing environmental impact.

A Vision for Sustainable Architecture

To achieve a future of eco-friendly construction, the industry must prioritize reducing waste and reusing materials. The revival of earthen walls and other traditional techniques represents a step forward. Future architecture must embrace a philosophy of sustainability, focusing not just on building but on renewing and reimagining existing structures.

By combining traditional methods with modern technology and shifting our perspective from creating new to preserving old, we can honor architectural heritage while building a more sustainable world.

Hitoshi Sato(Architect / CEO of Mokuzo-architect COCHI)

Mokuzou-architect COCHI do not buy the timber for their construction-projects from timber-markets, instead going to the mountains to buy directly from their trusted mountain foresters. With the slogan "To leave the world a beautiful landscape for 300 years to come", the company builds beautiful and resilient houses using the best materials, techniques, and designs. To build awareness of the origins of these trees, grown and tended by many generations of Yamamori, Kochi has started a tour that connects the mountains with the people who live in these special wooden houses.